special report

Operational Efficiency

Meat and poultry processors

leverage technology and strategic design

To explore current innovations and best practices supporting meat and poultry production efficiency, The National Provisioner spoke with Burns & McDonnell, JBT Marel, JLS Automation and Cargill.

Associate Group Editor

By Sammy Bredar

Meat and poultry processing facilities face a complex set of operational efficiency challenges, including labor availability, energy use and maintaining food safety while meeting increasing production demands. To explore current innovations and best practices supporting meat and poultry production efficiency, The National Provisioner spoke with Burns & McDonnell, JBT Marel, JLS Automation and Cargill.

According to Burns & McDonnell’s Brian Chrisman, senior business development manager, Niyush Sharma, project manager, and Dan Blake, EPC project manager, labor shortages have fundamentally changed how plants operate, prompting investments in automation, ergonomic improvements and process optimization to maintain throughput with smaller teams. Aging infrastructure and legacy equipment further complicate operations, creating bottlenecks that increase energy consumption and reduce overall efficiency.

Facilities must also reconcile efficiency with flexibility. Consumer demand for greater product variety, shorter production runs and faster changeovers challenges plants originally designed for high-volume, single-product operations. Burns & McDonnell noted that strategic retrofits, such as flexible processing lines, modern refrigeration and smart building controls, are increasingly essential for maintaining operational reliability while adapting to evolving production schedules.

Balancing throughput, energy consumption and product quality is a primary consideration during facility upgrades or redesigns. Burns & McDonnell explained that the approach begins with identifying system constraints and optimizing overall process flow, rather than focusing specifically on individual equipment. Aligning line speeds, buffer strategies and process capacities ensures stable production at the desired throughput. Energy efficiency is addressed through right-sized refrigeration, heat recovery and load-matched utilities, while product quality is maintained by minimizing handling, reducing dwell time and integrating automation where variability has the greatest impact.

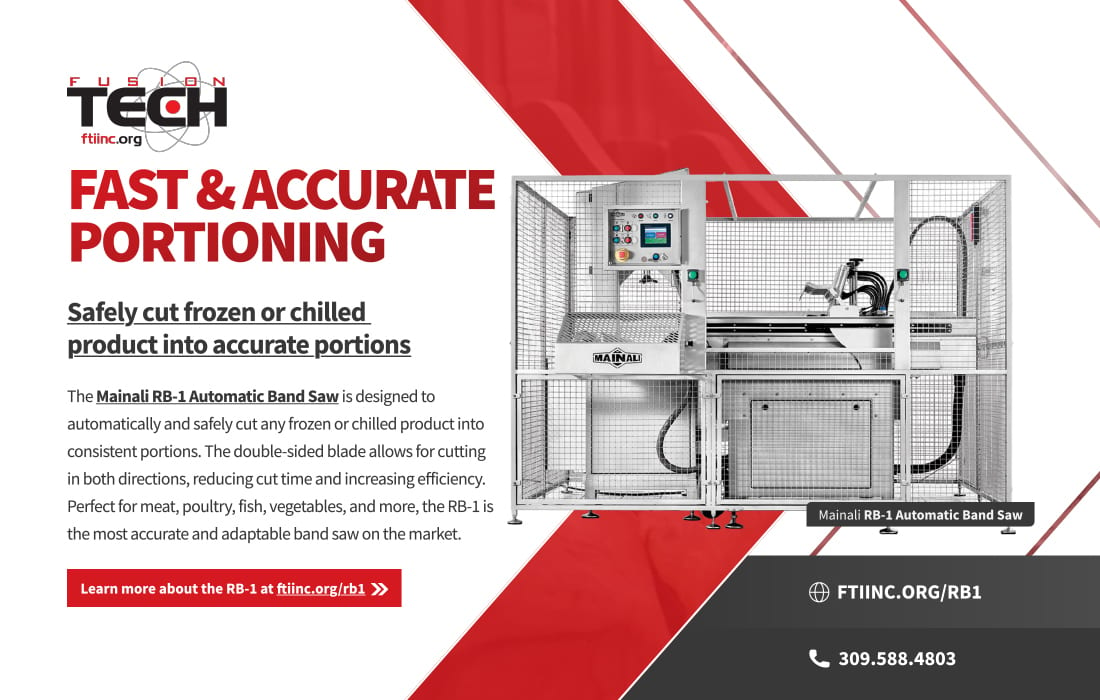

Several emerging technologies and process innovations are expected to drive efficiency gains in the next few years. Advanced robotics and automation are increasingly applied to labor-intensive tasks such as deboning and portioning, improving consistency while addressing workforce constraints. Real-time data platforms and analytics provide operators with insight into throughput, yield and equipment performance, enabling predictive maintenance and faster operational adjustments. Burns & McDonnell highlighted that modular and scalable processing lines, along with hygienic and easily cleanable equipment, are reducing downtime and shortening sanitation cycles. Energy-focused technologies, including variable-speed drives, intelligent refrigeration and heat recovery systems, further enhance operational efficiency and lower costs.

Plant size, layout and product type also shape efficiency strategies. High-volume commodity facilities benefit from standardized layouts, higher automation levels and balanced line capacities to support continuous production.

Smaller or more flexible plants producing value-added products prioritize modular layouts, quick changeovers, and scalable utilities to manage variability in product mix and demand. Legacy facilities often require targeted upgrades, such as improved buffering or selective automation, to unlock capacity without full rebuilds. Burns & McDonnell staff noted that efficiency strategies must align with throughput targets, product complexity, and physical constraints to achieve sustainable long-term improvements.

Automation has become a central tool for improving throughput without compromising quality. Michael Newcome, vice president of sales at JLS Automation, said processors increasingly view robotics as a precision tool, rather than just a speed multiplier. He noted that modern systems in portioning, weighing and handling provide consistent, repeatable decision-making that is difficult to maintain manually at scale. By integrating multiple process steps, upstream and downstream operations are synchronized, reducing handoffs and rework while improving consistency and yield.

Successful automation retrofits depend on understanding existing operations. Newcome explained that legacy facilities often present constraints around space, utilities and sanitation. Incremental upgrades allow operators to validate performance, build confidence and minimize disruption. “Retrofits are most successful when automation is designed to work with existing processes — rather than forcing the plant to adapt to a rigid system — and when maintainability and cleanability are addressed upfront, not as afterthoughts,” Newcome said.

Workforce skills are evolving alongside automation adoption. Operators are shifting from manual tasks to system oversight, troubleshooting, and optimization. Newcome emphasized that cross-training between operations, maintenance and engineering teams is increasingly common, with training focused on electrical, mechanical and controls fundamentals. Early investment in training, particularly during commissioning, enables faster adoption, higher uptime and stronger long-term returns from automation.

Dan Wolff, manager of sales engineering at JBT Marel’s A&B Process Systems, highlighted additional efficiency considerations, particularly around food safety. “Easy-to-clean technology is becoming increasingly important as efficient operations remain a priority,” he said.

Wolff noted that clean-in-place systems and equipment designed for rapid sanitation help minimize downtime while maintaining regulatory compliance. Workforce development is similarly critical, as facilities need employees capable of operating and maintaining increasingly automated systems. Wolff added that automation presents an opportunity to recruit younger workers familiar with advanced technology while providing safer, less physically demanding environments for an aging workforce.

Data-driven decision-making is transforming plant floor operations. Real-time monitoring allows processors to respond immediately to issues rather than waiting for end-of-shift or next-day reporting. Leon Fletcher, vice president of operations at Cargill, described CarVe, the company’s AI-powered computer vision system. “Until now, processors didn’t have an accurate, real-time way to see how much good meat might still be left on the bone. CarVe helps us to capture more red meat, identifying edible portions that traditional processing might miss.”

The AI-powered system provides instant visual feedback at the workstation, allowing employees to adjust knife motion and cutting technique on the spot. Fletcher said early trials show yield improvements of up to 0.5%, translating to millions of pounds of additional beef at scale. Beyond yield, the system functions as a training and development tool, enhancing product consistency, reducing rework, and improving throughput and safety. The technology emphasizes teamwork, coaching and real-time insight, complementing operator expertise rather than replacing it.

Processors adopting data-driven systems must measure success beyond traditional KPIs. Metrics such as throughput relative to design capacity, yield, labor efficiency, energy use and sanitation downtime provide a comprehensive view of operational efficiency. Fletcher noted that real-time data also supports sustainability goals, allowing facilities to monitor water, energy and other resource usage, set benchmarks and track improvements over time.

Across the industry, trends point toward increased flexibility, automation and data integration. Systems that handle more SKUs, faster changeovers and varying product inputs are in demand, supported by AI, robotics and connected analytics. Operators are empowered to make informed decisions in real time, while plants can maximize throughput, reduce waste and maintain product quality. Combining these tools with strategic workforce training ensures that efficiency gains are sustainable and aligned with long-term operational goals.

The operational efficiency landscape in meat and poultry processing is evolving rapidly. Facilities that integrate automation, energy-efficient systems, real-time data and skilled operators are positioned to maintain throughput, enhance product quality and optimize resource use. While challenges such as labor shortages, legacy infrastructure and evolving consumer demands persist, processors leveraging technology and strategic design are building resilient, high-performing operations for the future.

Opening photo credit: Cargill